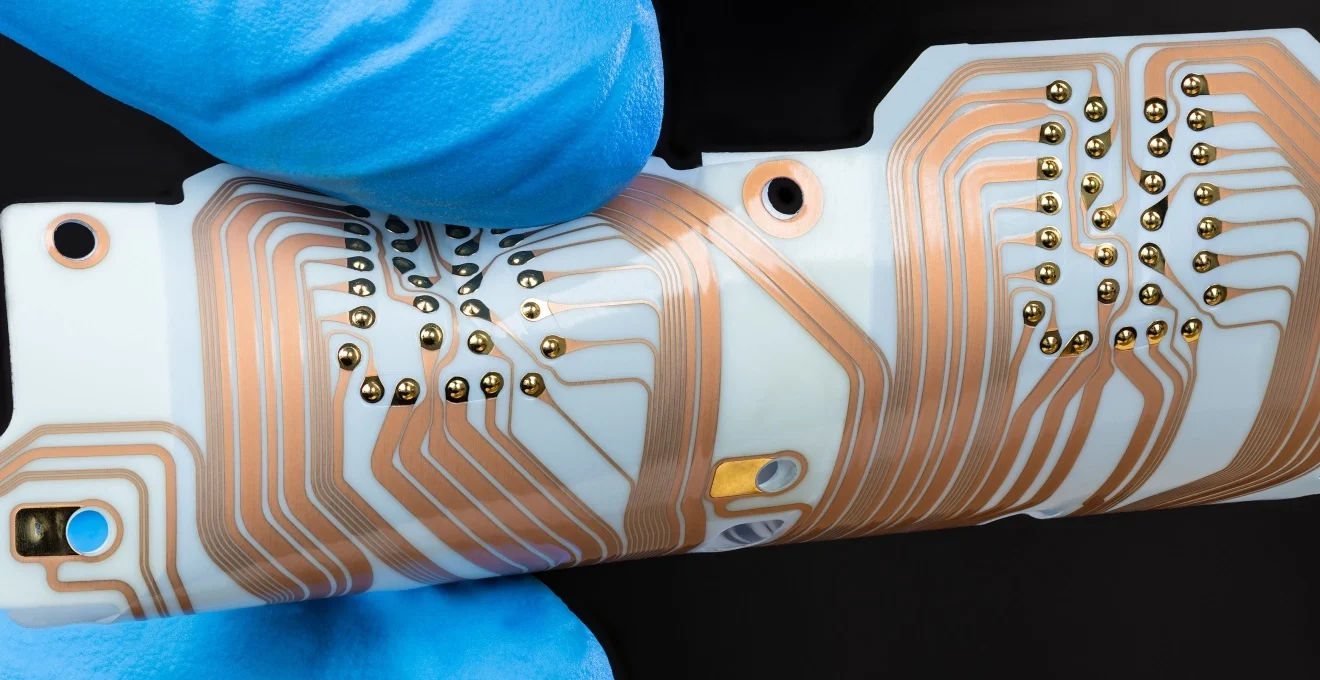

Flexible printed circuit boards (PCBs) have revolutionized the electronics industry, enabling the creation of smaller, lighter, and more versatile devices. These bendable circuits have paved the way for innovations in wearable technology, medical implants, and aerospace applications. As manufacturers strive to meet the growing demand for compact and efficient electronic products, Flex PCB technology continues to evolve, offering new possibilities for design and functionality.

The unique properties of flexible PCBs allow engineers to overcome space constraints and create products that conform to complex shapes. This adaptability has led to significant advancements in consumer electronics, healthcare devices, and industrial equipment. By reducing weight and size while maintaining or even improving performance, flexible PCBs have become an essential component in modern electronic design.

Evolution of flexible PCB technology in electronics manufacturing

The development of flexible PCB technology has been a game-changer in electronics manufacturing. Initially introduced in the 1950s for military and aerospace applications, flexible PCBs have since found their way into a wide range of consumer and industrial products. The evolution of materials and manufacturing processes has significantly improved the reliability and performance of these circuits.

One of the most significant advancements in flexible PCB technology has been the reduction in thickness and weight. Early flexible circuits were relatively bulky compared to today’s ultra-thin designs, which can be as thin as 0.1mm. This reduction in size has enabled the creation of increasingly compact devices without sacrificing functionality.

Another crucial development has been the improvement in flex cycle durability. Modern flexible PCBs can withstand thousands of flex cycles without failure, making them suitable for applications that require frequent bending or folding. This durability has opened up new possibilities in product design, particularly in the realm of foldable smartphones and wearable devices.

The miniaturization of electronic components and the development of advanced manufacturing techniques have pushed the boundaries of what’s possible with flexible PCB technology.

Key materials and design considerations for flexible PCBs

The performance and reliability of flexible PCBs largely depend on the materials used in their construction and the design considerations taken into account during the development process. Engineers must carefully select materials and design parameters to ensure that the final product meets the specific requirements of its intended application.

Polyimide vs. polyester substrate selection criteria

The choice between polyimide and polyester substrates is crucial in flexible PCB design. Polyimide is known for its excellent thermal stability, chemical resistance, and mechanical strength. It’s often the preferred choice for high-performance applications that require durability and reliability under extreme conditions. Polyester, on the other hand, offers a more cost-effective solution for less demanding applications and is commonly used in consumer electronics.

When selecting a substrate material, engineers consider factors such as:

- Operating temperature range

- Flexibility requirements

- Chemical exposure

- Cost constraints

- Dimensional stability

Copper foil thickness and conductivity optimization

The thickness of the copper foil used in flexible PCBs plays a critical role in determining the circuit’s electrical performance and mechanical properties. Thinner copper foils offer greater flexibility but may have higher electrical resistance. Conversely, thicker copper provides better conductivity but reduces flexibility.

Engineers must optimize copper foil thickness to balance conductivity requirements with the desired level of flexibility. Advanced manufacturing techniques, such as roll-to-roll processing, have enabled the production of ultra-thin copper foils with excellent conductivity, allowing for the creation of highly flexible and efficient circuits.

Adhesiveless vs. adhesive-based lamination techniques

The method of laminating copper foil to the substrate can significantly impact the performance and reliability of flexible PCBs. Adhesiveless lamination techniques, such as direct metallization, offer several advantages over traditional adhesive-based methods:

- Improved thermal performance

- Enhanced flexibility

- Better dimensional stability

- Reduced overall thickness

However, adhesive-based lamination may still be preferred in certain applications due to its lower cost and simpler manufacturing process. The choice between these techniques depends on the specific requirements of the application and the desired performance characteristics of the flexible PCB.

Dynamic flex lifecycle testing and durability standards

Ensuring the long-term reliability of flexible PCBs is crucial, especially in applications that involve frequent bending or flexing. Dynamic flex lifecycle testing is used to evaluate the durability of flexible circuits under repeated flexing conditions. These tests simulate real-world usage scenarios and help engineers identify potential failure points before the product reaches the market.

Industry standards, such as IPC-6013 for flexible and rigid-flex printed boards, provide guidelines for testing and qualifying flexible PCBs. These standards outline requirements for mechanical, electrical, and environmental performance, ensuring that flexible circuits meet the necessary quality and reliability benchmarks.

Miniaturization advancements enabled by flexible PCBs

Flexible PCB technology has been a key enabler of miniaturization in electronics, allowing for the creation of smaller, lighter, and more compact devices. This reduction in size and weight has had a profound impact on various industries, particularly in consumer electronics and wearable technology.

Wearable technology: apple watch and fitbit integration

The development of wearable devices like smartwatches and fitness trackers has been greatly facilitated by flexible PCB technology. These devices require compact, lightweight circuits that can conform to the curved surfaces of the human body. Flexible PCBs have made it possible to integrate complex electronic systems into small form factors, enabling the creation of devices like the Apple Watch and Fitbit trackers.

In these wearable devices, flexible PCBs are used to connect various components, such as displays, sensors, and batteries, while conforming to the device’s curved shape. This integration allows for efficient use of space and contributes to the overall comfort and usability of the product.

Smartphone camera modules and Flex-Rigid designs

The evolution of smartphone camera technology has been significantly influenced by flexible PCB designs. Camera modules in modern smartphones often utilize flex-rigid PCB configurations, which combine the benefits of both flexible and rigid circuit boards. This hybrid approach allows for the precise positioning of camera components while maintaining a compact form factor.

Flexible PCBs in smartphone cameras enable:

- Optical image stabilization mechanisms

- Compact autofocus systems

- Efficient heat dissipation

- Integration of multiple camera sensors

Automotive dashboard display interconnects

In the automotive industry, flexible PCBs have revolutionized dashboard design by enabling the integration of large, curved displays and complex control systems. These flexible circuits allow for seamless connections between various dashboard components, reducing the overall weight and complexity of the wiring harness.

Automotive manufacturers use flexible PCBs to create sleek, modern dashboard designs that incorporate touch screens, digital instrument clusters, and advanced infotainment systems. The flexibility of these circuits allows for innovative packaging solutions that optimize space utilization and improve overall vehicle design.

Flexible PCB applications in aerospace and defense

The aerospace and defense industries have been early adopters of flexible PCB technology, recognizing its potential to reduce weight and improve reliability in mission-critical systems. Flexible circuits are used in a wide range of applications, from satellite communications to avionics systems in military aircraft.

In satellite technology, flexible PCBs offer several advantages:

- Weight reduction, crucial for minimizing launch costs

- Improved thermal management in the vacuum of space

- Resistance to vibration and shock during launch and deployment

- Ability to conform to complex satellite structures

Military aircraft also benefit from flexible PCB technology, particularly in radar systems and electronic warfare equipment. These applications require high-performance circuits that can withstand extreme conditions while maintaining reliability and signal integrity.

The use of flexible PCBs in aerospace and defense applications has led to significant improvements in system performance, reliability, and overall mission success rates.

Medical device integration: implantables and diagnostic equipment

The medical industry has embraced flexible PCB technology for its ability to create small, lightweight, and biocompatible electronic devices. From implantable medical devices to advanced diagnostic equipment, flexible circuits have enabled significant advancements in healthcare technology.

Cochlear implants and retinal prostheses

Flexible PCBs have played a crucial role in the development of advanced neural prosthetics, such as cochlear implants and retinal prostheses. These devices require extremely compact and flexible circuits that can conform to the delicate structures of the inner ear or eye.

In cochlear implants, flexible PCBs are used to create the electrode array that stimulates the auditory nerve. The flexibility of these circuits allows for:

- Precise positioning of electrodes within the cochlea

- Minimization of trauma during insertion

- Improved long-term stability and performance

Similarly, retinal prostheses utilize flexible PCBs to create electrode arrays that can conform to the curvature of the eye, enabling the restoration of limited vision in patients with certain types of blindness.

Mri-compatible flex PCB designs

The development of MRI-compatible flexible PCBs has been a significant advancement in medical imaging technology. These specialized circuits are designed to function reliably in the intense magnetic fields of MRI machines without causing interference or safety hazards.

MRI-compatible flexible PCBs are used in various applications, including:

- Patient monitoring systems

- MRI-guided surgical tools

- Specialized RF coils for improved image quality

The use of non-ferromagnetic materials and careful circuit design allows these flexible PCBs to operate safely and effectively in the MRI environment, enhancing diagnostic capabilities and patient care.

Disposable medical sensors for patient monitoring

Flexible PCB technology has enabled the creation of disposable medical sensors that provide accurate, real-time patient monitoring. These sensors are often used in hospitals and clinics to track vital signs, such as heart rate, blood oxygen levels, and body temperature.

The advantages of flexible PCBs in disposable medical sensors include:

- Comfort and conformability to the patient’s skin

- Low-cost manufacturing for single-use applications

- Integration of multiple sensing elements in a compact package

- Improved hygiene through disposability

These sensors have become increasingly important in healthcare settings, providing continuous monitoring capabilities while reducing the risk of cross-contamination between patients.

Environmental impact and recyclability of flexible PCBs

As the use of flexible PCBs continues to grow, there is increasing focus on their environmental impact and recyclability. The electronics industry is working to develop more sustainable manufacturing processes and improve the end-of-life management of flexible circuits.

Several initiatives are underway to address the environmental challenges associated with flexible PCBs:

- Development of biodegradable substrate materials

- Implementation of halogen-free flame retardants

- Improvement of recycling processes for flexible circuits

- Design for disassembly to facilitate easier recycling

While flexible PCBs present some recycling challenges due to their multi-material construction, advances in recycling technologies are making it possible to recover valuable materials from these circuits. Some companies are exploring chemical recycling methods that can separate and recover the various components of flexible PCBs, including precious metals and polymers.

The industry is also focusing on reducing waste during the manufacturing process , implementing more efficient production techniques and material utilization strategies. These efforts not only reduce the environmental impact of flexible PCB production but also contribute to cost savings and improved resource efficiency.

As environmental regulations become more stringent, manufacturers are increasingly considering the entire lifecycle of their products, from design and production to disposal and recycling. This holistic approach is driving innovation in flexible PCB technology, leading to more sustainable and environmentally friendly electronic products.