For decades, the hum of diesel generators has been the default soundtrack for construction and temporary job sites—a symbol of power, but also of volatile fuel costs, relentless maintenance, and significant carbon emissions. As industries pivot towards sustainability and operational efficiency, a new solution is not just emerging but proving its strategic value: the intelligent Battery Energy Storage System (BESS). This is more than a simple battery-for-fuel swap; it represents a fundamental shift in how job sites manage, control, and optimize energy.

The real transformation lies in moving beyond the generator mindset of merely producing power to adopting a strategic approach of intelligent energy management. While diesel generators are a blunt instrument, modern BESS acts as a sophisticated, data-driven asset that actively reduces operational risks and unlocks new financial efficiencies. For a look at how this technology is materializing, you can visit this website to view the latest zero-emission intelligent storage systems that are redefining site power.

Your Job Site Power Strategy at a Glance

This article moves beyond surface-level benefits to provide a strategic deep-dive into intelligent BESS. We will deconstruct the Total Cost of Ownership (TCO), explore how smart control systems optimize energy for maximum ROI, analyze practical deployment realities, and show how modular designs deliver unparalleled flexibility for any job site scale.

Evaluating the move to mobile Battery Energy Storage Systems (BESS) requires looking past the initial price tag. While the upfront capital expenditure for BESS can be higher than for a traditional diesel generator, the long-term financial equation tells a very different story. The true return on investment is revealed through a comprehensive analysis of the Total Cost of Ownership (TCO), which accounts for significant operational savings in fuel, maintenance, and risk mitigation.

A study comparing diesel generators to BESS found that electricity costs could be up to 66% lower than diesel fuel expenses for the same load, drastically reducing operational expenditures. This financial upside, combined with growing government support, is fueling rapid adoption. The remarkable expansion is evident in the US battery storage commercial capacity growth from 47 MW in 2010 to over 11,000 MW in 2023. Beyond direct savings, BESS also minimizes project risks tied to volatile fuel prices and power outages, preventing costly performance penalties.

Companies are integrating BESS to meet ESG targets, reduce emissions, and gain energy independence.

– Elum Energy, Maximising Solar ROI with Battery Energy Storage Systems

To fully grasp the financial landscape, it’s essential to compare the initial investment against the lifecycle savings.

| Cost Factor | Upfront Investment | Operational Savings |

|---|---|---|

| Capital Expenditure | High | Low |

| Fuel Savings | Low | High |

| Maintenance Costs | Moderate | Reduced |

| Tax Incentives | Applicable | Enhances ROI |

Furthermore, the U.S. government offers substantial financial incentives to accelerate this transition. The Inflation Reduction Act (IRA) of 2022 notably expanded the Investment Tax Credit (ITC) to cover standalone battery storage, offering a significant credit on system costs. Businesses can leverage these programs to dramatically shorten their payback period.

How to Leverage US Financial Incentives for BESS

- Step 1: Evaluate project eligibility under current federal tax credits.

- Step 2: Ensure mobile BESS capacity is above 5 kWh for qualification.

- Step 3: Plan construction to start before 2033 to maximize ITC benefits.

- Step 4: Monitor domestic content requirements to qualify for bonus credits.

The core of an intelligent BESS is its brain: the Battery Management System (BMS). This is far more than a simple on/off switch. Advanced BMS platforms use sophisticated algorithms and even artificial intelligence to monitor battery health, manage charging and discharging cycles, and balance energy loads in real-time. This active management ensures optimal performance, extends the battery’s lifespan, and prevents system failures.

What is an intelligent BESS?

An intelligent BESS uses an advanced Battery Management System (BMS) with AI to actively control charging, optimize power delivery, and predict energy needs for maximum efficiency and battery longevity.

These smart systems enable predictive power management, using data analytics to forecast a job site’s energy needs and adjust output proactively. This is particularly valuable for peak shaving—the practice of using stored battery power during periods of high demand to avoid expensive charges from the utility grid or overloading a generator. As BslBatt Insights highlights, this intelligent oversight is key to durability and performance.

Battery management systems use AI and machine learning to predict faults and optimize battery lifespan.

– BslBatt Insights, How Battery Management Systems Work In Energy Storage Applications

The efficiency gains are not trivial. Studies have shown up to a 20% improvement in energy efficiency through advanced analytics, translating directly into lower operational costs. Moreover, an intelligent BMS is crucial for integrating renewable energy sources like solar panels, allowing a job site to run as a self-sufficient hybrid system and further reducing grid reliance.

This image showcases the intricate technology at the heart of an intelligent BESS.

The visual representation of data flows and connectivity underscores how these systems process vast amounts of information to make split-second decisions for energy optimization.

The core features of these advanced systems deliver tangible benefits for any job site operation.

| Feature | Benefit |

|---|---|

| Real-time monitoring | Early fault detection |

| AI-based fault prediction | Extended battery life |

| Cloud integration | Remote management |

| State-of-charge optimization | Improved safety and performance |

While the benefits of mobile BESS are compelling, successful deployment requires navigating practical challenges. One of the primary hurdles is establishing a reliable charging infrastructure, especially on remote or off-grid sites. Planning for efficient and timely charging is critical to maintaining operational continuity and avoiding downtime.

Insights from Amwins highlight that operational issues include battery degradation, safety protocols, and charging infrastructure difficulties, underscoring the necessity of rigorous standards and training. Safety, in particular, is non-negotiable. Although rare, system failures can occur, with a report noting 15 failure incidents reported in 2023 including fires and explosions. This highlights the importance of adhering to strict safety protocols and ensuring personnel are thoroughly trained in handling and operating these high-capacity energy systems.

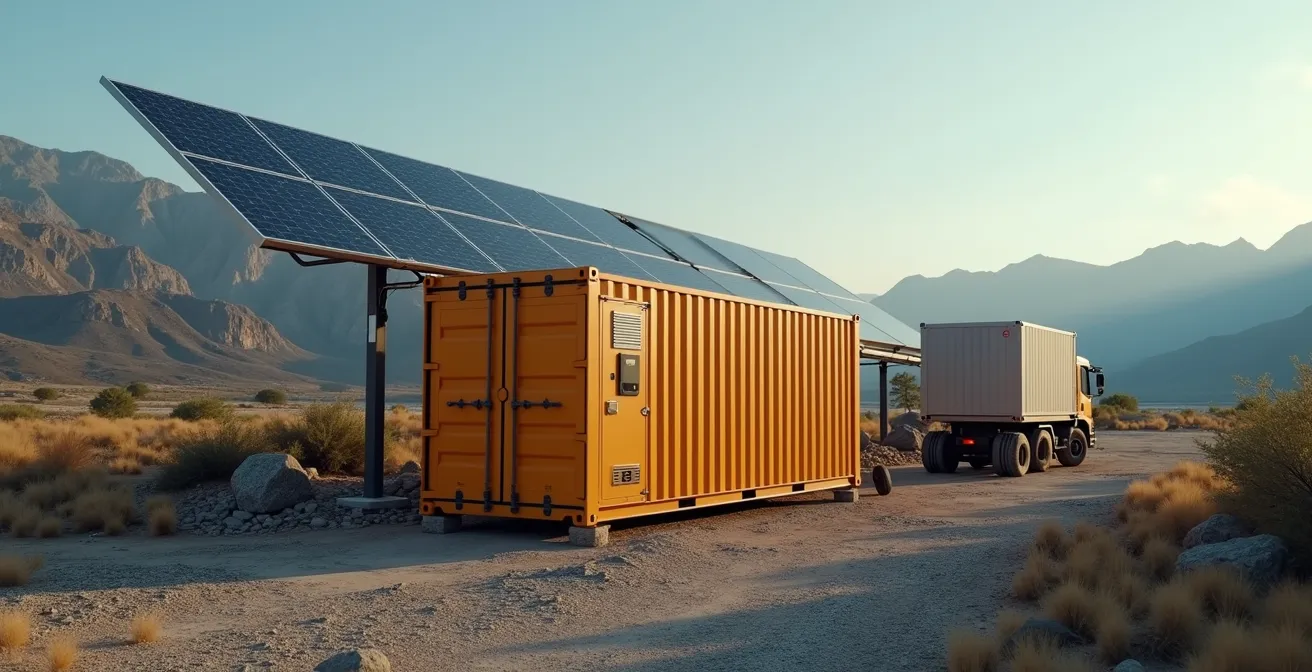

This image depicts a mobile BESS being charged by solar panels in a remote setting, a practical solution to the infrastructure challenge.

Such hybrid setups demonstrate how BESS can be integrated with renewables to create self-sufficient power solutions even in the most challenging environments.

A comprehensive understanding of the battery’s lifecycle is also essential. This includes accounting for natural degradation over time, planning for eventual replacement, and considering end-of-life recycling options. To mitigate these challenges, adhering to established best practices is crucial.

Best Practices for BESS Deployment and Safety

- Conduct thorough site assessments.

- Implement detailed safety protocols for battery handling.

- Train personnel on operational procedures and emergency response.

- Establish regular maintenance and diagnostic checks.

Finally, it’s important to evaluate BESS against other emerging technologies. While BESS is a leading solution, alternatives like hydrogen fuel cells are also gaining traction as part of the broader ecosystem of modern mobile power solutions. A complete analysis ensures the chosen technology is the best fit for a project’s specific needs. For those interested in this comparison, you can Explore hydrogen vehicle benefits.

One of the most powerful features of modern BESS technology is its modularity. Unlike monolithic diesel generators, modular BESS units can be scaled up or down to precisely match the energy demands of a specific job site or project phase. This flexibility ensures that companies only pay for the capacity they need, avoiding the inefficiency of running an oversized generator for a small load.

This adaptability is crucial for the construction industry, where energy requirements can fluctuate dramatically—from powering a small site office initially to later charging heavy electric machinery. As BslBatt notes, modular designs improve scalability, simplify maintenance, and enhance energy system reliability. This approach allows for seamless integration with existing power sources, whether it’s the grid, diesel generators, or on-site renewables like solar.

Modular BESS Deployment in Utility and Cooperative Projects

Two contrasting projects illustrate how modular BESS configurations provide flexibility in pricing, delivery, and performance to meet diverse scale needs. A large utility-scale project and a smaller cooperative initiative both successfully used modular designs to tailor energy storage capacity precisely to their requirements, optimizing cost and performance without over-provisioning resources.

The market is rapidly embracing this flexible approach, with data showing that modular systems adoption increased by 35% year-over-year in large-scale applications. This growth is a direct result of the tangible benefits modularity offers in terms of cost-efficiency and operational agility.

The image below illustrates the concept of modularity, with interconnected units ready to be configured for specific power outputs.

This visual metaphor highlights the “building block” nature of modern BESS, enabling true site electrification. As the construction industry increasingly adopts electric vehicles and equipment, scalable and modular BESS will become the central hub for powering a fully electric, zero-emission job site.

Key Takeaways

- True BESS value is found in Total Cost of Ownership (TCO), not just the initial purchase price.

- Intelligent Battery Management Systems (BMS) are crucial for optimizing performance, safety, and battery lifespan.

- Practical challenges like charging infrastructure and safety protocols require careful planning for successful deployment.

- Modular BESS designs offer unparalleled flexibility, allowing power solutions to scale with project needs.

What is the main advantage of BESS over diesel generators?

The main advantage is a significantly lower Total Cost of Ownership (TCO). While the upfront cost may be higher, BESS saves money through reduced fuel expenses, minimal maintenance, and quiet, emission-free operation, which also improves site safety and environmental compliance.

Are there financial incentives for adopting mobile BESS in the US?

Yes, the federal government offers significant incentives, most notably the Investment Tax Credit (ITC) expanded by the Inflation Reduction Act. This can provide a tax credit for up to 30% of the system’s cost, drastically reducing the initial investment and shortening the payback period.

How long do mobile BESS units last?

The lifespan of a mobile BESS depends on the battery chemistry, usage cycles, and the quality of its Battery Management System (BMS). High-quality lithium-ion systems, managed by an intelligent BMS, are typically designed to last for thousands of charge-discharge cycles, often translating to a lifespan of 10 years or more.

Can BESS power heavy electric machinery on a job site?

Absolutely. Modern BESS are designed with modularity in mind, allowing them to be scaled to meet high-power demands. They can effectively power equipment like tower cranes, hoists, and charging stations for electric construction vehicles, enabling full site electrification.